CUSTOMER TESTIMONIALS

Heat Wheels by SG America

SG America’s heat wheel cassettes may be dwarfed in size by the large overhead doors of their manufacturing plant, but make no mistake, these giant metal discs and their powder-coated frames can be over fifteen feet high and weigh more than anything else in the building.

The frame of this massive cassette has just arrived from Van Industries, where they were professionally powder coated for better durability.

Ming-I Chou, SG’s Senior Design Engineer, explains that the heat wheel is a “green” technology that transfers heat between supply and exhaust airstreams in large, custom heating and cooling systems for hospitals, universities and other buildings requiring large volumes of ventilation air.

“Depending on the season, the wheel will remove or recover heat and moisture within the ventilation system to save energy,” Chou said. “Both are transferred by the aluminum ‘honeycomb’ of which the wheel is made.”

In a heating, ventilation and air conditioning (HVAC) system, summer heat and moisture in outdoor air are removed from air coming into the building so that less money is spent on air conditioning inside the building. In the wintertime, heat and moisture are recovered from exhaust air and used to pre-heat and humidify outside air brought into the building to save on winter heating costs.

According to their website, www.sgamerica.com, Hi-Panex™ heat wheels reduce up to 80% of the humidity load of outside air used for ventilating office buildings, schools, hospitals, nursing homes and hotels.

Enjoying a healthy and fruitful professional relationship with Van Industries, Van Industries powder coats the larger frames for SG America. “They are very responsive and easy to work with,” added Chou. “They deliver in a timely manner and are always willing to go the extra mile.”

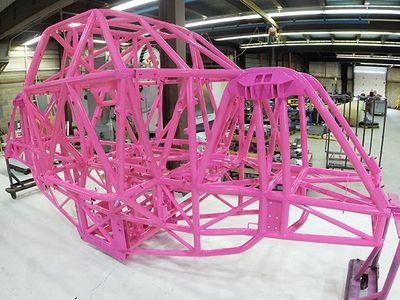

J&B Motorsports and Their 'BeWare' Monster Truck

J&B Motorsports owner Jim Jacobs has nothing but kind words to say about Van Industries as he drops off a fairly gigantic metal monster truck frame.

"They're amazing," Jacobs says while helping lower the frame from it's place on a flatbed truck. "I've gotten a lot of things done from them."

He was on hand to deliver his current project, the monster truck frame, to be powder coated "sassy pink" by Van Industries for an upcoming appearance of the truck named "BeBreast Cancer AwarenessWare."

"It's called 'BeBreast Cancer AwarenessWare' but it means 'be aware' for cancer awareness," he said. "The driver will be female and the truck will be used for breast cancer awareness."

While on the shop floor at Van, "BeBreast Cancer AwarenessWare" will undergo several processes before coated in its polished pink final state.

J&B Motorsports Jacobs is excited to see the finished project, as he runs through a list of various jobs he's brought to Van Industries. He's gone so far as to recommend Van to his customers, as well.

"Van has done a number of things for me, like some rear housings and dragster chassis," he said. "They've always done a good job."