MIG and Arc Welding: What's the Difference?

- By Matt Godek

- •

- 09 Dec, 2016

- •

Test your welding knowledge!

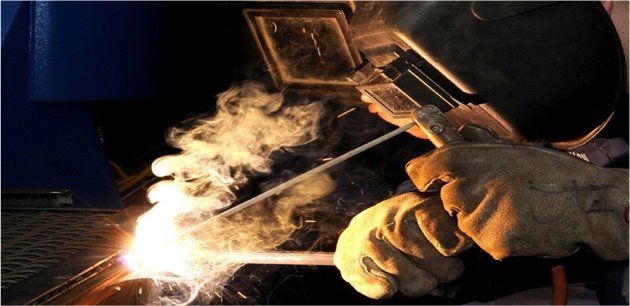

While MIG welding represents a large segment of our business here at Van Industries, arc welding—or stick welding, as it’s often called—continues to be an essential service that we offer our customers. But what’s the difference between these two methods? Here’s a brief comparison:

MIG Welding

MIG (Metal Inert Gas) welding

requires three things: electricity to produce heat, an electrode to fill the joint, and shielding gas to protect the weld from the air. MIG welders consist of a welding gun with a trigger that controls the feed of a small electrode. The wire is fed from a spool and is accompanied by the protective gas. The operator monitors the amount of weld being used to join the two base metals. The process can be automated by using robots.

Because the wind can make it nearly impossible to get a solid weld, almost all MIG welding is done indoors.

Because the wind can make it nearly impossible to get a solid weld, almost all MIG welding is done indoors.

Basic Arc Welding

What happens when a piece of equipment can’t be brought indoors for a repair weld? Well, you take your arc welder outside and complete the job there. Arc welding, appropriately called shielded metal arc welding (SMAW), uses the electricity from the welder and passes it through a rod. At the point of contact it arcs and creates a temperature that can reach 7,000° F. Now the rod begins to melt, and the coating around it creates a shield from any oxygen that could contaminate the weld.

What do MIG and Arc welding have in common?

- Safety:

All welding is dangerous. Proper equipment and techniques are required!

- Joint preparation:

The joint area must be clear of rust, oil, water, and paint

- Electrode selection:

The wire or rod must be right for the material

- Machine set-up:

Amperage and polarity must be set correctly

- Technique:

While any welding is a science, it is also very much an art

Trust Van Industries with all your welding and fabrication needs

Welding should be left to the experts. Let our professionals assist you with your next welding project. Click here to learn more about our welding services

or call us at 610-582-1118.