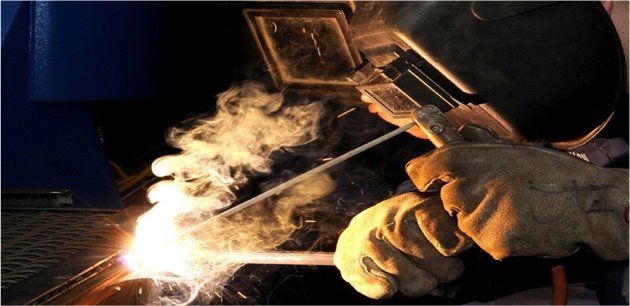

Robotic Welding Advantages

Robotic welding has several advantages, but sometimes manual welding can be a good choice, too.

Let’s say you’re looking to have some parts fabricated, and welding is one of the operations. In your search for the right fabricator, you notice that some of the shops have both robotic and manual capabilities while others offer only manual welding services. Should it matter to you how the job is completed, as long as the price is competitive and the quality is acceptable?

The short answer is “Yes, it should!” Depending on the quantities you need, the turnover time you require, and the type of weld you must have, robotic welding can offer several benefits over manual welders.

Here are a few key advantages of Robotic Welding:

Welding consistency

When all of the production factors are managed properly, robotic welding yields highly consistent results. The software that is used to create a program for your parts ensures that every one of them will be welded to the specifications of your project and that all of your completed products will have the characteristics you expect.

Welding accuracy

By reducing human error through automation, you can count on your products being welded accurately every time. The accuracy from robotic welding also cuts waste, reduces manpower, which means there will be less reworking such as machining, grinding, and additional welding. All of this can translate into lower per-part costs for you.

Welding speed

Sometimes you need your parts yesterday. While robotic systems can’t perform that miracle, they can maintain an ideal production speed over 24-hour shifts with minimal downtime. Unlike manual welders, there are no fatigue factors, meetings, or breaks to consider in scheduling your products.

Sometimes manual welding can be the right choice

Of course, sometimes stick welding—or another standard welding method--is the best way to handle your job, and we can help you there, too.

At Van Industries, we have a full range of robotic and manual welding services. We offer the area's largest robotic welding cell,

which includes a Motoman EA 1900N Robotic MIG welder that can make short work of your parts. With a vertical reach of 134 inches and a horizontal reach of 75 inches, plus dual rotary headstock/tailstock positioners, our Motoman is waiting to tackle your most demanding production runs!

We can help with all your welding needs!

Click here to learn more about our welding services. If you’d like to discuss the best option for your welding project, please contact us online or call us at 610-582-1118 .